1. Introduction

A greenhouse is a framed structure made of GI pipe/MS angle/ Wood/ Bamboo and covered with a transparent/translucent material fixed to frame with grippers. Besides irrigation, it has control/monitoring equipment, which is considered necessary for controlling environmental factors such as temperature, light, relative humidity etc. and is necessary for maximizing plant growth and productivity. Thus, the greenhouse is an enclosed area, in which crops are grown under partially or fully controlled conditions. The cladding material is of plastic (Polyethylene) film and acts like a selective radiation filter that allows solar radiation to pass through it but traps the thermal radiation emitted by the inside objects to create greenhouse effect.

The greenhouse protects the plants from adverse climatic conditions and provides an appropriate amount of light, temperature, humidity, carbon- dioxide etc. to achieve optimum yield with excellent quality. The reason for building a greenhouse is to get faster growth by raising humidity and controlling temperatures. Labor, energy and capital are the major three cost factors in a typical modern greenhouse production system. Greenhouse technology is highly relevant under Indian conditions due to variant agro-climatic conditions of the country.

2. Advantages

- Provides favorable micro climatic conditions for the

- Cultivation in all seasons is

- Higher yield with better quality per unit

- Conserves moisture thus needs less

- More suitable for cultivating high value/ off – season

- Helps to control pest and

- Helps in hardening of tissue cultured

- Helps in raising early

- Round the year propagation of planting material is

- Protects the crops from wind, rain, snow, bird, hail

- Generates self- employment opportunities for educated

3. Potentialities of greenhouse technology

- Cultivation is possible under extreme climatic

- Export of hybrid seeds, ornamentals plants and tissue culture

- Suitable for Biotechnology and genetic

- Cultivation of rare and exotic medicinal, aromatic and ornamental species.

- Production of high value, low volume horticultural

- Supply of high quality fresh fruits/vegetables and flowers for

- Production of healthy planting

The choice of crops to be raised in a greenhouse depends on the size of the structure and economics of crop production.

4. Types of greenhouse

Keeping in view the Indian climatic conditions, two types of greenhouse have been taken into consideration under the Govt. of India schemes (NHM & HMNEHS) for subsidy, and they are Naturally Ventilated Greenhouse and Greenhouse with Fan & Pad Cooling System. There is also a provision of subsidy for the low cost greenhouses made of wooden and bamboo structure.

- Naturally ventilated greenhouse – best suited for areas where temperature ranges between 15 oC to 30 o The structure should have a provision of sufficient number of openings for ventilation. The percentage of ventilation will be up to 60% of the floor area depending upon climatic conditions. The openings may be side wall vent or roof vent or both to exchange air (hot/cold) flow inside the greenhouse. During the summer period the openings are provided need to ensure efficient air movement and should be fully airtight during winter period.

- Greenhouse with fan and pad cooling system – best suited for hot dry climatic conditions such as Northern plains where temperature goes above 30 oC,. The system is working on the principle that when water evaporates and heat is absorbed from This is possible by drawing cool air into greenhouse through wet pad located at one end of the wall, where hot air is replaced by co-axial fans mounted on the opposite end of wall. The excessive temperature causes various damages to the morphology and physiological processes of plants such as flower shedding, leaf scorch, poor fruit quality, excessive transpiration, shortened life span of the plants and low net photosynthesis due to excessive respiration etc. Hence, it is important to maintain air temperature inside the greenhouse ranging between 20 oC to 28 oC for better crop growth.

Operation of Fan & Pad cooling system

Fan and pad system is controlled by a thermostat. Thermostatically controlled fans let the outside air into the greenhouse and remove inside air out of it. The capacity of fan should be 1m3 for each m3 of greenhouse volume per minute so as to ensure a complete renewal (or at least three quarters of it) or (50 to 60 renewals per hour) under tropical conditions.

Orientation criteria for mounting fan & pad

The orientation of the multi span greenhouse with fan & pad cooling system should be made in such a way to take advantages of prevailing wind direction. Wet pad should be mounted on the wall of greenhouse facing winds and fan on the leeward side. The temperature gradients inside the greenhouse decide the need for Fan & Pad system. The root vents should be on the leeward side to prevent structural damage to the greenhouse.

Factors to reduce uneven temperature are as follows:

- Seal all cracks and holes in the

- Limit the maximum distance between fan & pad to 25

- Increase the number of fans for efficient air

- Provide additional misting facility that saves

- In case of saline/brackish water, use horizontal pad as water flows downwards through the pads has a self cleaning

- The water used for wetting the pad should be stored in an underground tank and provision to be made for

- Uniform water pressure of the system must be maintained to keep the pad adequately

- The cooling efficiency of greenhouse can be increased by using shadenet of up to 50% shade

5. Design considerations for greenhouse

5.1 Site selection

While selecting the site for construction of a greenhouse, following points should be considered for the optimum growth and development of plant:

- The site should be free from

- The site should be at a higher level than the surrounding land with adequate drainage

- Availability of good quality irrigation water and electricity to run the fan & pad cooling

- pH of the irrigation water should be in the range of 5 to 7.0 and EC between 0.1 to 0.3 mS/cm.

- pH of the soil should be in the range of 5 to 6.5 and EC between 0.5 to 0.7 mS/cm respectively.

- Proximity to motorable road to take advantages of market for inputs supply & sale

- Soil need to be changed or sterilized after every 3 to 4 years preferably to avoid built up of soil Alternatively, artificial media can be an option for cultivation.

5.2 Orientation

Correct orientation can provide good environmental conditions inside the greenhouse. Following points should be considered while deciding the orientation of a greenhouse depending upon light intensity and direction & velocity of wind.

- Orientation of the single span greenhouse should be directed towards East-West and North – South in case of multi-span for taking advantage of available sun-shine.

- Gutter should be made in North – South direction in multi span

- Slope along the gutter should not be more than 2%.

- Slope along the gable side should not be more than 25%.

- In naturally ventilated greenhouse, ventilators should open on the leeward

- Single span greenhouse should have long axis perpendicular to the direction of wind to protect it from wind

- Wind breaks, should be placed at least 30 meters away on North – West side of the

In case of tropical region, there is low availability of solar radiation and sky remains cloudy during the rainy season. Hence, effective ventilation is very important to control the temperature and humidity by keeping proper orientation of the greenhouse.

5.3 Size

The size of the greenhouse needs to be selected based on availability of the land. The cost may vary depending upon the types of greenhouse and number of suppliers’ present in the region. Depending upon the market access and experience of greenhouse cultivation, it is suggested to start with a naturally ventilated greenhouse having minimum size of 100 sqm as it would require less initial capital investment along with operational expenditure. However, experienced farmers / entrepreneurs may decide to go for larger size greenhouse depending on their scale of operation and project costs.

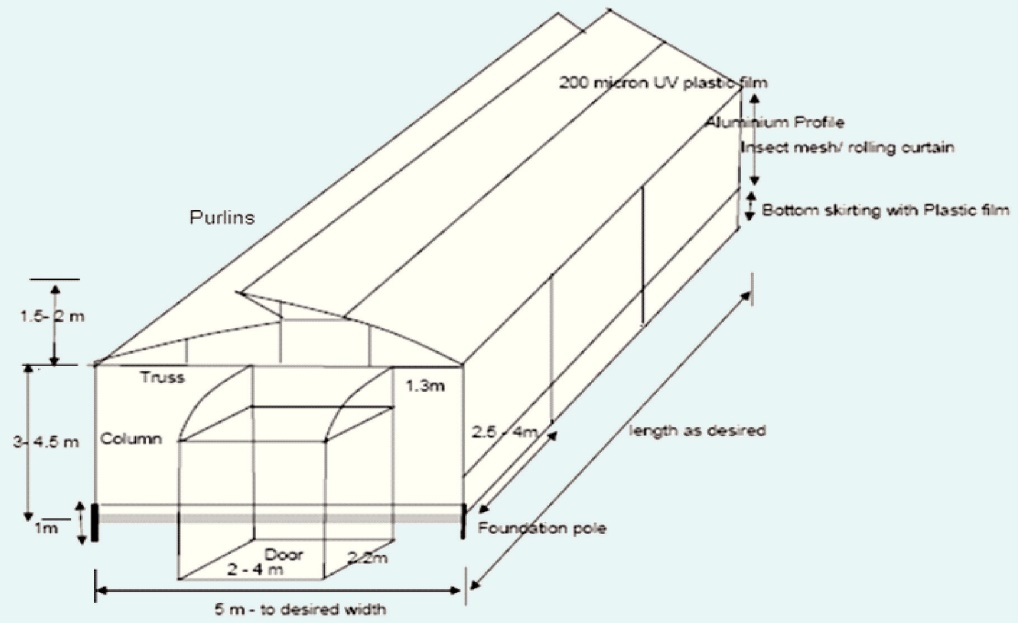

5.4 Height

Height is one of the most important aspects of greenhouse design. The height of the structure directly impacts natural ventilation, stability of the internal environment and crop management. The ideal centre height of naturally ventilated small greenhouse (up to 250 sqm) should be in the range of 3.5 m to 4.5 m and 5.5 m to 6.5 m in case of large size greenhouses. The side/gutter height should be in between 2.5 m to 3 m and 4.5 m to 5 m for small and large size greenhouses respectively. Both types of greenhouse can be made in single or multi-span structures. A multi-span greenhouse can be constructed for an area more than 200 sqm and is economical in terms of construction material & required control/ monitoring equipments. Height of the greenhouse having fan & pad cooling system should be slightly lesser than the naturally ventilated greenhouse and in any case not be more than 5.5 m.

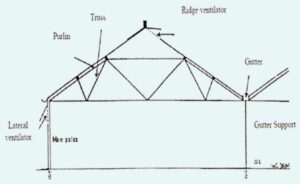

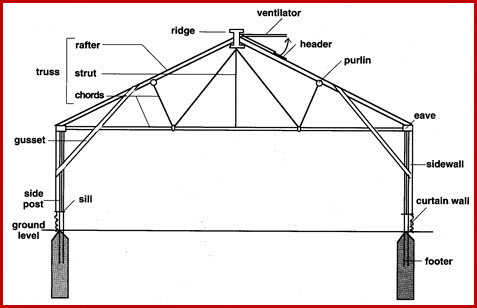

5.5 Parts of the greenhouse

6. Indian standards for Greenhouse

The Bureau of Indian standards (BIS) has formulated following standards with respect to greenhouse technology:

- IS 14462: 1997 – Recommendations for layout, design and construction of greenhouse structures

- IS 14485: 1998 – Recommendations for heating, ventilating and cooling of greenhouse

- IS 15827: 2009 – Plastics films for greenhouses – specifications

7. Criteria for selecting greenhouse structure

As far as possible, galvanized iron (GI) pipe based greenhouse must conform to ISI Trade mark with minimum 2 mm wall thickness. The structure should have following features:

- Stub type-anchoring foundation, Galvanized and nut bolted structure having options for future

- Strong enough to withstand various types of load such as Live load, Dead load, Crop load, Wind and Snow

- Single piece G.I. gutter 500 mm wide & 1 mm

- Aerodynamic shape along all peripheries to resist high wind

- The structure is designed to resist wind velocity up to 150 Km/hr.

- Provision for fixing of UV stabilized plastic film with aluminum/G.I. profiles & zigzag spring

- Strong enough to support the load of internal service systems and plant foliage.

- Use 200 micron UV stabilized plastic film conforming to Indian Standard IS 15827:

- Easy to service, cover and recover with cladding

- Easy to

- Cost

8. Technical specifications

Considering the above criteria, suggested technical specifications suggested for a naturally ventilated greenhouse are given in annexure 1A & 1B and for greenhouse with fan & pad cooling system in annexure 2.

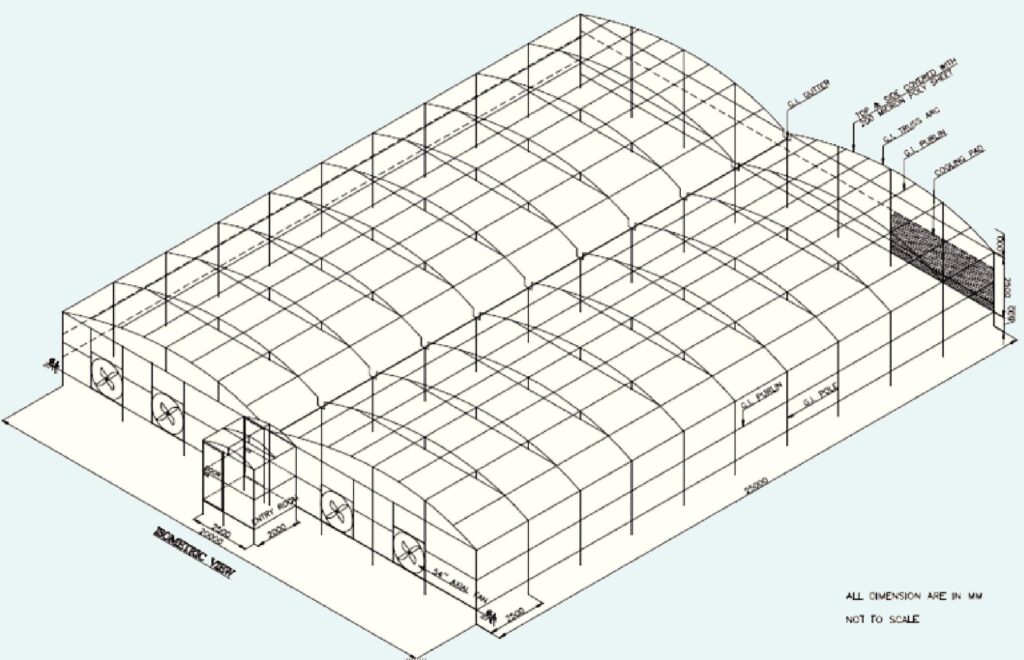

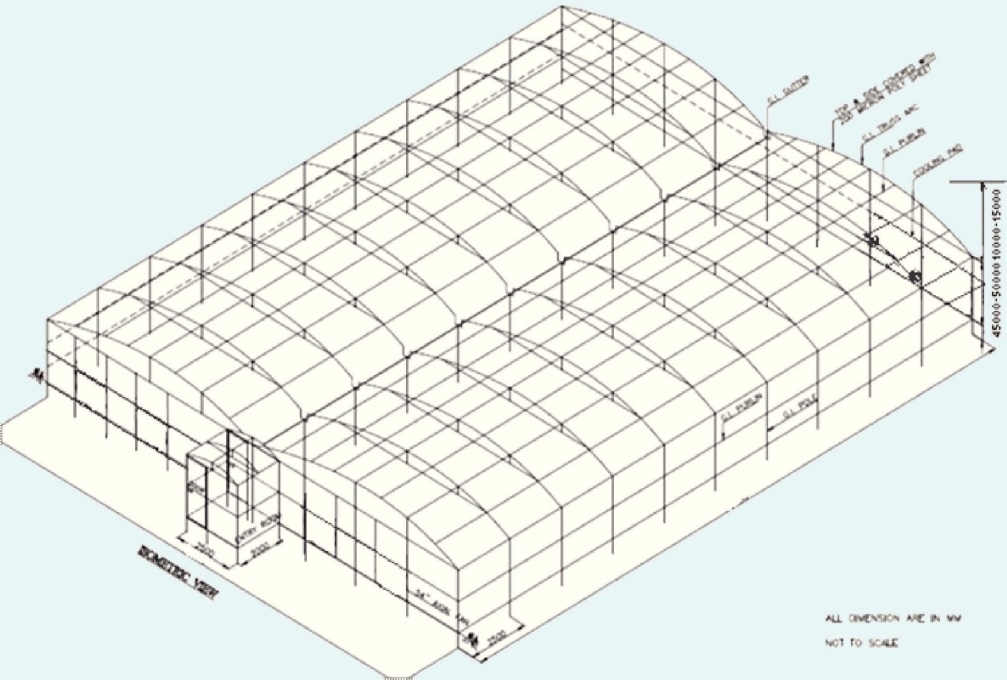

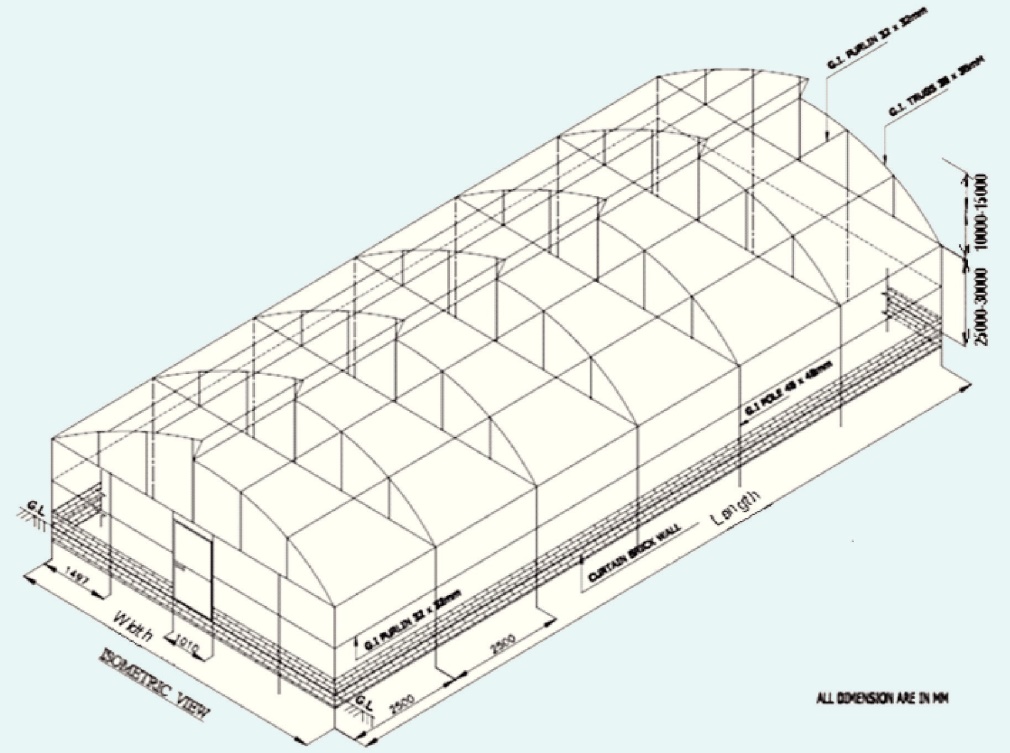

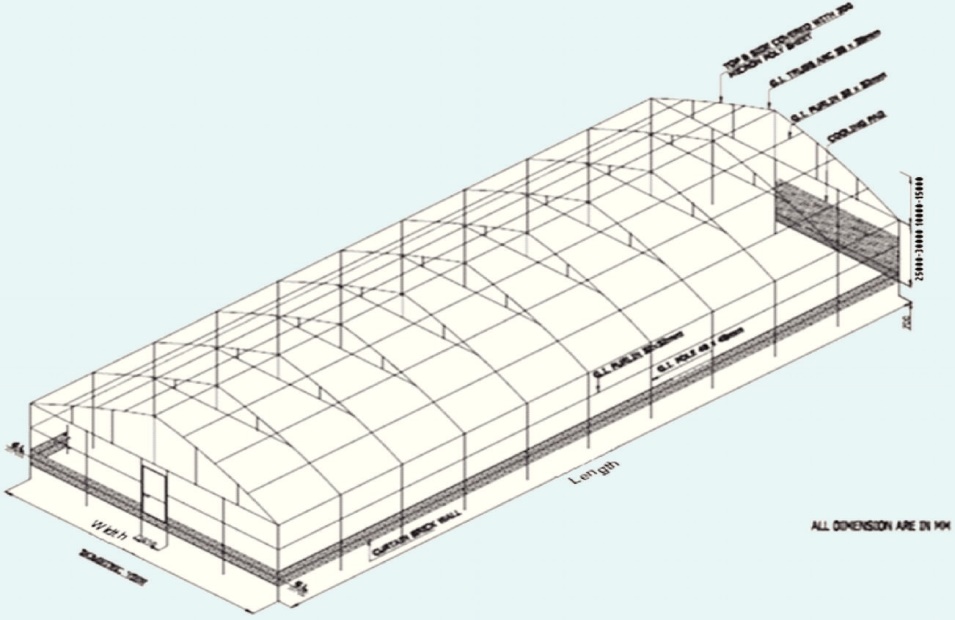

9. The design drawing of different types

of greenhouse

The basic designs of various types of greenhouse are given in annexure 3.

10. Wood/ Bamboo based naturally

ventilated greenhouse/ Rain-shelter

greenhouse

Wooden/Bamboo based naturally ventilated greenhouse (also called rain- shelter in heavy rain fall areas) are made of Casurina, Nilgiri, etc or Bamboo. The poles made of these materials preferably may be treated either with turpentine or coal tar at one end that will be placed in the foundation pits. Aluminum profiles with spring or wooden battens may be used for fixing the UV stabilized polyethylene films. The wooden/bamboo poles and other supporting materials used in the greenhouse structure need to be strong enough to withstand different types of load – wind load, crop load etc. To withstand such loads, the recommended specifications of outer diameter of wooden/bamboo poles lies between 8 cm -10 cm for main poles and 6 cm – 8 cm for purlins & trusses. Preferably, all parts of the structure are fitted with the help of nails or nut-bolts.

The suggested technical specifications for a wooden or bamboo structure greenhouse are given in annexure 4.

11. Cladding materials

There are two types of plastic films normally used for greenhouse cladding

– single layer (monolayer) clear transparent UV stabilized film and specialty

films such as diffused, anti drip, anti-dust, anti-sulphur etc. The selection of the film would depend on the crops to be grown in the greenhouse and various chemical treatments given during the production cycle. As per the Indian Standard (IS 15827: 2009) the plastic films should have following important properties:

Important properties of covering materials

Sl. No. | Type of plastic films | Characteristics | Uses |

| i) | Normal film | a) Good Transparency more than 80% b) Low Greenhouse Effect | Forcing and Semi- Forcing crops |

| ii) | Thermic clear film | a) Good Transparency b) High infrared (IR) effectiveness | As normal film, when greater infrared (IR) effectiveness is desired |

| iii) | Thermic diffusion | a) Diffusion Light b) High infrared (IR) effectiveness | As normal film, when greater infrared (IR) effectiveness and diffusing light is desired |

12. Important Climatic factors

influencing plant growth

The importance of climatic factors and its desired level influences physiological characteristics of crops in a greenhouse are given below:

Sl. No. | Climatic Factors | Important for | Desirable level in Greenhouse |

| 1. | Radiation / Light | Photosynthesis, Photo- morphogenesis Photoperiodism | 50,000 lux* |

| 2. | Temperature | Cell division & elongation, respiration, photosynthesis water uptake, transpiration etc. | 18 0C – 25 0C |

| 3. | Relative humidity | Quality of plant | 60% – 80% |

| 4. | Carbon dioxide (CO2) | Photosynthesis | 350 ppm – 1000 ppm |

| 5. | Air movement/ wind movement | Influences temperature, relative humidity & CO2 concentration in the greenhouse, structural stability | Inflow: Outflow ratio should be 1:1 per hour |

| 6. | Rainfall/ precipitation | Influences RH, structural stability | — |

Source: Internet researchable *1 lux = 1 lumen/square meter

13. Important Research Studies

(through PFDCs) on flowers, vegetables

& nursery cultivation

Based on the research studies carried out by the Precision Farming Development Centres (PFDCs) and others on different crops, information on suggested crop cycle, climatic requirement, cost of cultivation & payback period best suited for greenhouse cultivation is given below. However, the above may vary from place to place and as per the experiences of growers.

13.1 Suggested crop cycle

| Crops | Periods/Crop cycle month | |

| Transplanting | Harvesting | |

| Tomato | Varieties available for round the year cultivation | |

| Green Capsicum / Colour Capsicum – Spinach 2 season or Okra | August – September April – May February | April – March July – August May – June |

| Cucumber – Cauliflower / Leafy vegetable / Okra | November – December April – May | March – April October – November |

| Muskmelon / Water melon | February – March | June |

| Propagation of fruit crops etc. | 3 cycle round the year | |

| Flowers | Round the year | |

13.2 Climatic requirement for flowers & vegetables

The climatic factors such as temperature, relative humidity and light intensity and their desired level for optimum growth of some selected crops is given below:

Sl. No | Name of crop | Temperature (0C) | Humidity (%) | Light Intensity (lux) | ||||

| Day | Night | |||||||

| Flowers | ||||||||

| 1. | Carnation | 16 – 20 | 10 – 12 | 60 – 65 | 40000 – 50000 | |||

| 2. | Chrysanthemum a) Cut flower b) Pot | 22 – 24 23 – 26 | 15 – 16 16 – 19 | 60 – 65 60 – 65 | 35000 – 40000 35000 – 40000 | |||

| 3. | Gerbera | 20 – 24 | 18 – 21 | 60 – 65 | 40000 – 50000 | |||

| 4. | Orchid | 22 – 24 | 18 – 20 | 70 – 80 | 25000 – 30000 | |||

| 5. | Anthurium | 22 – 25 | 18 – 20 | 70 – 80 | 25000 – 30000 | |||

| 6. | Rose | 24 – 28 | 18 – 20 | 65 – 70 | 60000 – 70000 | |||

| Vegetables | ||||||||

| 7. | Tomato | 22 – 27 | 15 – 19 | 50 – 65 | 50000 – 60000 | |||

| 8. | Cucumber | 24 – 27 | 18 – 19 | 60 – 65 | 50000 – 60000 | |||

| 9. | Capsicum | 21- 24 | 18 – 20 | 50 – 65 | 50000 – 60000 | |||

| Nursery | ||||||||

| 10. | Nursery | 22 – 27 | 16 -19 | 50 – 65 | 50000 – 60000 | |||

Source: Internet researchable

13.3 Indicative cost of cultivation of crops grown under greenhouse

| Crops | Avg. cultivation cost (`/sq m) | |

| Vegetables | Capsicum & Tomato | 105 |

| Flower | Gerbera & Carnation | 500 |

| Nursery | Mango, Guava & Aonla etc. | 225 |

13.4 Indicative payback period of 500 sqm Green-house.

The average payback period of 500 sqm greenhouse in case of nursery production is 10 – 11 months, flowers 18 – 19 months and vegetables 22 – 23 months respectively.

Annexure 1A: Suggested Technical specifications of Naturally Ventilated Greenhouse

| Sl. No. | Items | Description/Specifications |

| 1 | Product | Naturally Ventilated Greenhouse |

| 2 | Size | 100 m2 – 300 m2 |

| 3 | Bay size | 6 m x 3-4m, Width of greenhouse should be at least 35 % of the desired length. |

| 4 | Ridge height | 3.5 m to 4.5 m |

| 5 | Vents | Ridge vent should have 80-90 cm and side vent depending upon the requirement and opening |

| should be fixed with 40 mesh UV stabilized nylon insect screen. | ||

| 6 | Gutter height | 2.5 m to 3 m from floor area |

| 7 | Gutter slope | 2% slope need be provided in civil foundation work/ structure |

| 8 | Gutter material | 20 gauge or 1 mm thick GI sheet with perimeter of 500 mm or more preferably of single length without joint |

| 9 | Structural design | The structural design need to be sound enough to withstand wind speed minimum 150 km/hr and minimum load of 25 kg/m2. There should be provision for opening one portion at either side for entry of small tractor/power tiller for intercultural practices. The firm needs to highlight design features and list of greenhouse clients. |

| 10 | Structure | Complete structure made of galvanized steel tubular pipes or equivalent section conforming Indian Standards having wall thickness 2mm, structural member should be joined with fasteners properly. |

| Columns | 48/42 mm OD, 2 mm thick | |

| Trusses | Bottom & top cord 42 mm OD, 2 mm thick | |

| Trusses member & Purlin | 33 mm OD, 2 mm thick | |

| Purlin member & others | 25 mm, 2 mm thick | |

| Foundations | Insert GI pipes of minimum 42 mm OD or more to have foundation depth of 48 cm or more depending upon soil type and prevailing wind condition, grouted with cement concrete mixture of 1:2:4 using telescopic insertion of column. | |

| Fasteners | All nuts & bolts must be of high tensile strength and galvanized. | |

| 11 | Entrance room & Door | One entrance room of size 3 m x 3 m x 3 m (L x W x H) need to be provided and covered with 200 micron UV stabilized transparent plastic film. Two hinge doors of size 2 m width & 2.5 m height double leaf made in plastic/FRP sheets mounted in suitable strong frame. |

| 12 | Cladding material | UV stabilized 200 micron transparent Plastics films conforming Indian Standards (IS 15827: 2009), multilayered, anti drip, anti fog, anti sulphur, diffused, clear and having minimum 85% level of light transmittance. |

| 13 | Fixing of cladding materials | All ends/joints of plastic film need to be fixed with two way aluminum profiles with suitable locking arrangement along with curtain top. Wooden batons or PVC grippers need not be used. |

| 14 | Spring Insert | Zigzag high carbon steel with spring action wire of 2-3 mm diameter must be inserted to fix shade net into Aluminum Profile. |

| 15 | Curtains and insect screen | Roll up UV stabilized 200 micron transparent plastic film as curtains need be provided should be equal to height on all sides having automatic type motor operated crank mechanism. However, provision for manual opening and closing of curtains need also be provided.40 mesh nylon insect proof nets (UV stabilized) of equivalent size need to be fixed inside the curtains. Anti flapping strips is suggested to ensure smooth functioning of the curtain. |

| 16 | Shadenet | UV stabilized 50% shading net with motor/ manually operated mechanism for expanding and retracting. Size of net should be equal to the floor area of greenhouse. |

| 17 | Drip Irrigation System with fogging & misting facility | Drip irrigation system under greenhouse need to be selected on the basis of crop spacing (design on spacing 45cm x 45 cm) along with fogging and misting facilities. The spacing considered for calculation The suggested bill of materials are Sand Filter 5 m3/hr, Screen Filter 10 m3/hr, Control Valve 63 mm, Control Valve 50mm, By-pass Assembly – 1.5″, Air Release Valve 1″, Non Return Valve1.5″, Throttle Valve 1.5’’, Flush Valve 50mm, Venturi 1.5″ Assembly with manifold, PVC pipe 63 mm/6 kg/ cm2, PVC pipe 50 mm/6 kg/cm2, PE plane lateral 16 mm, Emitting pipe lateral 16mm- @ 0.45m spacing, hanging type micro sprinkler nozzle (four-way take- off assembly) for very fine water particles (foggers & mister) to be fixed in PE pipe of diameter 16mm, Water tank of capacity 2000 liter and fittings & accessories. |

| 18 | Footpath | 1m wide and 10 cm thick footpaths should be provided in the centre (length x width) & made of cement concrete ratio of 1:2:4. |

| 19 | Curtain wall/ Apron | 22 cm brick wall of 1m height (24 cm below and 80 cm above ground level on all the four sides. The wall needs to be plastered and water proofing cement with 1:6 ratio. |

| After sales services (The firm have to provide) | ||

| 20 | Warranty | Free maintenance for one year from the date of installation. |

| 21 | Training | Free training for operation, maintenance & production for one year. |

| 22 | Testing | All plastic materials used in the greenhouse should be tested by the CIPET for quality assurance (If necessary). |

Annexure 1B: Suggested technical specifications of Naturally Ventilated Greenhouse

| Sl. No. | Items | Description/Specifications | ||

| 1 | Product | Naturally Ventilated Greenhouse | ||

| 2 | Size | 500 m2 /1000 m2 | ||

| 3 | Bay size | 8m x 4m, Width of greenhouse should be at least 35 % of the desired length. | ||

| 4 | Ridge height | 6.5m to 7m | ||

| 5 | Ridge Vent | 80-90 cm opening fixed with 40 mesh nylon insect screen | ||

| 6 | Gutter height | 4 – 4.5 m from floor area | ||

| 7 | Gutter slope | 2% slope need be provided in civil foundation work/ structure | ||

| 8 | Gutter material | 20 gauge or 1 mm thick GI sheet with perimeter of 500 mm or more preferably of single length without joint | ||

| 9 | Structural design | The structural design need to be sound enough to withstand wind speed minimum 150 km/hr and minimum load of 25 kg/m2. There should be provision for opening one portion at either side for entry of small tractor/power tiller for intercultural practices. The firm needs to highlight design features and list of greenhouse clients. | ||

| 10 | Structure | Complete structure made of galvanized steel tubular pipes or equivalent section conforming Indian Standards having wall thickness 2mm, structural member should be joined with fasteners properly. | ||

| 11 | Columns | 76 mm OD, 2 mm thick | ||

| Trusses | Bottom & top cord 60 mm OD, 2 mm thick | |||

| Trusses member | 48 mm OD, 2 mm thick | |||

| Purlin | 42 mm OD, 2 mm thick | |||

| Purlin member & others | 33/25 mm, 2 mm thick | |||

| Foundations | Insert GI pipes of minimum 60 mm OD or more to have foundation depth of 75 cm or more depending upon soil type and prevailing wind condition, grouted with cement concrete mixture of 1:2:4 using telescopic insertion of column. | |||

| Fasteners | All nuts & bolts must be of high tensile strength and galvanized. | |||

| Entrance room & Door | One entrance room of size 3 m x 3 m x 3 m (L x W x H) need to be provided and covered with 200 micron UV stabilized transparent plastic film. Two hinge doors of size 2 m width & 2.5 m height double leaf made in plastic/FRP sheets mounted in suitable strong frame. | |||

| 12 | Cladding material | UV stabilized 200 micron transparent Plastics films conforming Indian Standards (IS 15827: 2009), multilayered, anti drip, anti fog, anti sulphur, diffused, clear and having minimum 85% level of light transmittance. | ||

| 13 | Fixing of cladding materials | All ends/joints of plastic film need to be fixed with two way aluminum profiles with suitable locking arrangement along with curtain top. Wooden batons or PVC grippers need not be used. | ||

| 14 | Spring Insert | Zigzag high carbon steel with spring action wire of 2-3 mm diameter must be inserted to fix shade net into Aluminum Profile. | ||

| 15 | Curtains and insect screen | Roll up UV stabilized 200 micron transparent plastic film as curtains need be provided up to 3.0 m height on all sides having automatic type motor operated crank mechanism. However, provision for manual opening and closing of curtains need also be provided.40 mesh nylon insect proof nets (UV stabilized) of equivalent size need to be fixed inside the curtains. Anti flapping strips is suggested to ensure smooth functioning of the curtain. | ||

| 16 | Shadenet | UV stabilized 50% shading net with motor/ manually operated mechanism for expanding and retracting. Size of net should be equal to the floor area of greenhouse. | ||

| 17 | Drip Irrigation System with fogging & misting facility | Drip irrigation system under greenhouse need to be selected on the basis of crop spacing (design on spacing 45cm x 45 cm) along with fogging and misting facilities. The spacing considered for calculation The suggested bill of materials are Sand Filter 5 m3/hr, Screen Filter 10 m3/hr, Control Valve 63 mm, Control Valve 50mm, By-pass Assembly 1.5″, Air Release Valve 1″, Non Return Valve 1.5″, Throttle Valve 1.5’’, Flush Valve 50mm, Venturi1.5″ Assembly with manifold, PVC pipe 63 mm/6 kg cm2, PVC pipe 50 mm/6 kg/cm2, PE plane lateral 16 mm, Emitting pipe lateral 16mm- @ 0.45m spacing, hanging type micro sprinkler nozzle (four-way take off assembly) for very fine water particles (foggers & mister) to be fixed in PE pipe of diameter 16mm, Water tank of capacity 5000 liter and fittings & accessories. | ||

| 18 | Footpath | 1m wide and 10 cm thick footpaths should be provided in the centre (length x width) & made of cement concrete ratio of 1:2:4. | ||

| 19 | Curtain wall/ Apron | 22cm brick wall of 1m height (24 cm below and 80 cm above ground level on all the four sides. The wall needs to be plastered and water proofing cement with 1:6 ratio. | ||

| After sales services (The firm have to provide) | ||||

| 20 | Warranty | Free maintenance for one year from the date of installation. | ||

| 21 | Training | Free training for operation, maintenance & production for one year. | ||

| 22 | Testing | All plastic materials used in the greenhouse should be tested by the CIPET for quality assurance (If necessary). | ||

Annexure 2: Suggested technical specifications of Greenhouse with Fan & Pad cooling System

| Sl. No. | Items | Description/Specifications | |||||

| 1 | Product | Greenhouse with Fan & Pad Cooling | |||||

| 2 | Size | 500 m2 /1000 m2 | |||||

| 3 | Bay size | 8m x 4m, Width of greenhouse should be at least 35% of the desired length. | |||||

| 4 | Ridge height | 5 m to 5.5 m | |||||

| 5 | Ridge Vent | 80-90 cm opening fixed with 40 mesh nylon insect screen | |||||

| 6 | Gutter height | 4 m to 4.5 m from floor area | |||||

| 7 | Gutter slope | 2% slope need be provided in civil foundation work/ structure | |||||

| 8 | Gutter material | 20 gauge or 1 mm thick GI sheet with perimeter of 500 mm or more preferably of single length without joint | |||||

| 9 | Structural design | The structural design need to be sound enough to withstand wind speed minimum 150km/hr and minimum load of 25 kg/m2. There should be provision for opening one portion at either side for entry of small tractor/power tiller for intercultural practices. The firm needs to highlight design features and list of greenhouse clients. | |||||

| 10 | Structure | Complete structure made of galvanized steel tubular pipes or equivalent section conforming Indian Standards having wall thickness 2mm, structural member should be joined with fasteners properly. | |||||

| Columns | 76 mm OD, 2 mm thick | ||||||

| Trusses | Bottom & top cord 60 mm OD, 2 mm thick | ||||||

| Trusses member | 48 mm OD, 2 mm thick | ||||||

| Purlin | 42 mm OD, 2 mm thick | ||||||

| Purlin member & others | 33/25 mm, 2 mm thick | ||||||

| Foundations | Insert GI pipes of minimum 60 mm OD or more to have foundation depth of 75 cm or more depending upon soil type and prevailing wind condition, grouted with cement concrete mixture of 1:2:4 using telescopic insertion of column. | ||||||

| Fasteners | All nuts & bolts must be of high tensile strength and galvanized. | ||||||

| 11 | Entrance room & Door | One entrance room of size 3 m x 3 m x 3 m (L x W x H) need to be provided and covered with 200 micron UV stabilized transparent plastic film. Two hinge doors of size 2mwidth & 2.5 m height double leaf made in plastic/FRP sheets mounted in suitable strong frame. | |||||

| 12 | Cladding material | UV stabilized 200 micron transparent Plastics films conforming Indian Standards (IS 15827: 2009), multilayered, anti drip, anti fog, anti sulphur, diffused, clear and having minimum 85% level of light transmittance. | |||||

| 13 | Fixing of cladding materials | All ends/joints of plastic film need to be fixed with two way aluminum profiles with suitable locking arrangement along with curtain top. Wooden batons or PVC grippers need not be used. | |||||

| 14 | Spring Insert | Zigzag high carbon steel with spring action wire of 2-3 mm diameter must be inserted to fix shade net into Aluminum Profile. | |||||

| 15 | Co-axial fan | Co axial fan (ISI mark) of minimum 1200 mm diameter containing 6 numbers of GI sheet blades, frame is of GI sheet materials followed by aluminum louver. | |||||

| 16 | Cellulose pad for cooling | Cellulose pad of thickness 4″ – 6″ thick, height: 5’, width as desired equipped with anodized Aluminum frame. Cooling pad complete with all necessary framing material (aluminum) as required for distribution and return, gutter, down spout cap and drip pan, plumbing kit, pump 220 Volt single phase, 50 cycle, drilled PVC piping cap, pad retainer, all suspension hardware, metal flashing required to seal pad for vent opening over flow 20 mm PVC & 40 mm standard sink drain. | |||||

| 17 | Circular pump with accessories for cooling pad | Circular pump with required capacity & accessories to be provided for wetting & circulating the pad area. | |||||

| 18 | Digital controller with sensory devices | The necessary digital controller with sensory device & accessories of standard quality (at least two units for 500 sqm area) should be provided to operate the fan & pad system to control temperature & humidity inside the Greenhouse. | |||||

| 19 | Electric wiring inside greenhouse | Use copper wire to withstand desired load of required electrical gadgets/appliances with ISI mark. | |||||

| 20 | Shadenet | UV stabilized 50% shading net with motor/ manually operated mechanism for expanding and retracting. Size of net should be equal to the floor area of greenhouse. | |||||

| 21 | Drip Irrigation System with fogging & misting facility | Drip irrigation system under greenhouse need to be selected on the basis of crop spacing (design on spacing 45cm x 45 cm) along with fogging and misting facilities. The spacing considered for calculation The suggested bill of materials are Sand Filter 5 m3/hr, Screen Filter 10 m3/hr, Control Valve 63 mm, Control Valve 50mm, By-pass Assembly 1.5″, Air Release Valve 1″, Non Return Valve 1.5″, Throttle Valve 1.5’’, Flush Valve 50mm, Venturi 1.5″ | |||||

| Assembly with manifold, PVC pipe 63 mm/6 kg cm2, PVC pipe 50 mm/6 kg/cm2, PE plane lateral 16 mm, Emitting pipe lateral 16mm- @ 0.45m spacing, hanging type micro sprinkler nozzle (four-way take off assembly) for very fine water particles (foggers & mister) to be fixed in PE pipe of diameter 16mm, Water tank of capacity 5000 liter and fittings & accessories. | |||||||

| 22 | Footpath | 1m wide and 10 cm thick footpaths should be provided in the centre (length x width) & made of cement concrete ratio of 1:2:4. | |||||

| 23 | Curtain wall/ Apron | 22cm brick wall of 1m height (24 cm below and 80 cm above ground level on all the four sides. The walls need to be plastered and water proofing cement with 1:6 ratio. | |||||

| Note: Optional items – provision to be made for opening & closing of ventilation system in case of power failures. | |||||||

| 24 | Curtains and insect screen | Roll up UV stabilized 200 micron transparent plastic film as curtains need be provided up to 3.0 m height on all sides having automatic type motor operated crank mechanism. However, provision for manual opening and closing of curtains need also be provided.40 mesh nylon insect proof nets (UV stabilized) of equivalent size need to be fixed inside the curtains. Anti flapping strips is suggested to ensure smooth functioning of the curtain. | |||||

| After sales services (The firm have to provide) | |||||||

| 25 | Warranty | Free maintenance for one year from the date of installation. | |||||

| 26 | Training | Free training for operation, maintenance & production for one year. | |||||

| 27 | Testing | All plastic materials used in the greenhouse should be tested by the CIPET for quality assurance (If necessary). | |||||

Annexure 3: Basic design and specifications of saw tooth type greenhouse.

The average payback period of 500 sqm greenhouse in case of nursery production is 10 – 11 months, flowers 18 – 19 months and vegetables

Annexure – 4 Suggested technical specifications for Wooden/Bamboo based

greenhouse/Rainshelter greenhouse

| Sl. No. | Items | Description/Specifications |

| 1. | Product | Naturally Ventilated Greenhouse (Wood/Bamboo based) |

| 2. | Size | 100 m2 – 250 m2 |

| 3. | Width of greenhouse | At least 35 % of the desired length of greenhouse |

| 4. | Ridge height | 3.5 m to 4 m |

| 5. | Ridge Vent | 80 cm to 90 cm opening fixed with 40 mesh nylon insect screen |

| 6. | Gutter height | 2.25m – 2.75 m from floor area |

| 7. | Gutter slope | The gutter slope should be at least 2% in foundation structure |

| 8. | Structural design | The structural design should be sound enough to withstand wind speed minimum 130 km/hr and minimum load of 20 kg/m2. There should be provision for opening one portion at either side for entry of small power tiller for intercultural practices. |

| 9. | Structure | Complete structures are made of strong Wooden Bamboo posts. The post should have dimension 8 cm -10 cm diameter for central post, side post and Gutter post/ tie beam etc. and diameter 6 cm – 8 cm for Post Plate, Supporting post, Trusses/ members/ sticks/others structural members for joining each other properly. |

| Treatment of poles | The post must be treated with different type of preservatives to protect it from termites/ fungal attacks. The recommended preservatives are Coal Tar Creosote, Copper Zinc Naphthenates and Abietates, Boric Acid and Borax, Copper-Chrome- Arsenic (CCA) Composition, Acid-Curpric-Chromate Composition & Copper-Chrome-Boric Composition. | |

| Fasteners | All nuts & bolts, nails, Aluminum /MS strip of 2 cm width must be of high tensile strength and galvanized & if required, there should be provision of PP/ Coir & Jute ropes for anchoring the structure. | |

| 10 | Entrance room & Door | Two entrance door of size 2.5m x 1.5m must be provided as per the requirements and covered with 200 micron UV stabilized transparent plastic film. |

| 11 | Cladding material | UV stabilized 200 micron transparent Plastic films conforming Indian Standards (IS 15827: 2009), multilayered, anti drip, anti fog, anti sulphur, diffused, clear and having minimum 85% level of light transmittance. |

| 12 | Fixing of cladding materials | All ends/joints of plastic film need be fixed with two way aluminum profile with suitable locking arrangement along with curtain top. |

| 13 | Spring Insert | Zigzag high carbon steel with spring action wire of 2-3 mm diameter must be inserted to fix shade net into Aluminum Profile. |

| 14 | Curtains and insect screen | Roll up UV stabilized 200 micron transparent plastic film as curtains need be provided up to recommended gutter height on all sides having provision for manual opening and closing of curtains should also be provided.40 mesh nylon insect proof |

| nets (UV stabilized) of equivalent size need to be fixed inside the curtains. Anti flapping strips is suggested to ensure smooth functioning of the curtain. | ||

| 15 | Shadenet | UV stabilized 50% shading net with manually operated expanding and retracting mechanism. Size of net should be equal to floor area of the greenhouse. |

| 16 | Footpath | 1m wide and 10 cm thick footpaths should be provided in the centre (length x width) & made of cement concrete 1:2:4. |

| After sales services | ||

| 17 | Warranty | The firm to provide Warranty free maintenance for one year from the date of installation. |

| 18 | Testing | All plastic materials used in the greenhouse should be tested by the CIPET for quality assurance (If necessary). |

| 19 | Training | Free training for operation, maintenance & production for one year. |

15. Subsidy on Greenhouse

Government of India has been providing subsidy @ 50% of the total cost indicated below for adoption of this technology by farmers with a maximum ceiling up to 4000 square meter per beneficiary under National Horticulture Mission (NHM) and Horticulture Mission for North East & Himalayan states (HMNEH).

| Items | Pattern of Assistance (Rs. /Sqm) up to 4000 Sqm. per beneficiary | ||

| Tubular structure | Wooden structure | Bamboo structure | |

| Greenhouse with Fan & Pad system | 1465 | — | — |

| Naturally Ventilated Greenhouse | 935 | 515 | 375 |

Disclaimer: The data, information and suggestions contained in this document are given purely as a guide. We undertake no responsibility for the results derived from their adoption. Please consult authorized official person before implementing related project.